- Higher energy efficiency ratings to meet and exceed local and regional residential building codes.

- Continuous exterior wall and roof construction is tighter than traditionally framed walls and roofing, dramatically reducing air infiltration and lowering energy bills.

- SIPs panels allow for more consistently comfortable heating and cooling levels.

- Reduced cost of HVAC installation due to the use of lower tonnage equipment. Oversizing the HVAC equipment can reduce its life, while needlessly increasing utility costs.

- Provides greater insulation from noise outside of the home.

- Unlike spray foam insulation, EPS does not off-gas and this contributes to a healthier home environment.

- Longer ceiling spans without the need for support structures, such as rafters. This allows for more spacious, vaulted ceiling designs.

Save Energy Costs and

Increase Home Comfort with SIPs

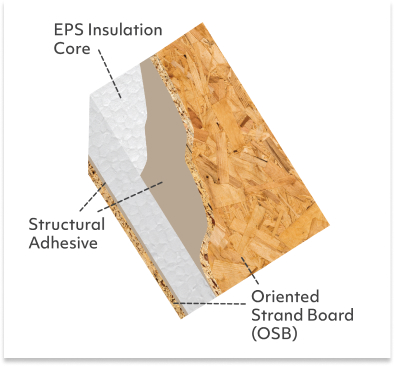

Structural Insulated Panels (SIPs) can more efficiently replace the traditional framing and insulation commonly used in the upper levels, gable ends, and roofing of log homes and log cabins. These integrated panels are constructed of structural OSB surrounding a hard core of EPS insulation, providing exceptional energy efficiency, as well as environmental safety and comfort in your home. SIPs advantages in our log cabins and homes include:

Combined with the energy efficiency and thermal mass properties of log walls on the first floor, the application of SIPs on the second floor exterior walls, upper walls of the gable ends, and roofing will provide long lasting energy cost savings, along with health and home comfort benefits.

The Science of SIPs

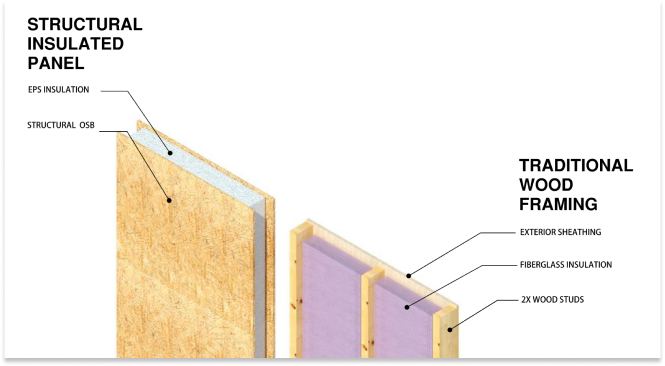

SIPs replaces the wood studs, separate insulation materials, and the sheathing commonly used on the exterior upper walls, gables, and roofing of a log home. The use of SIPs creates a continuous barrier around the perimeter of the home to control temperature levels and minimize air infiltration. Structural Insulated Panels provide increased R-Value for the life of your log home and cabin.

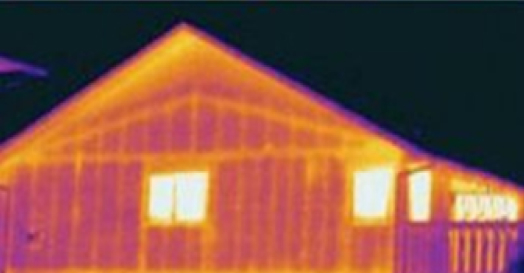

Thermal Imaging

Structural Insulated Panels reduces the number of studs typically used in conventional framing, which act as thermal bridges and reduce energy efficiency. Combined with the thermal properties of a log wall on the main floor, it will provide the optimum level of energy efficiency for your log home.

-

Structural Insulated Panels

-

Traditional Framing

With thermal imaging SIPs walls and roofing show a continuous thermal barrier. Traditional framing image shows areas of possible air infiltration.

Structural Insulated Panels Materials

-

Structural Insulated Panels Materials

There are a wide range of ratings related to Oriented Strand Board. SIPs utilize structural OSB, which has more density and cross panel strength than basic OSB, and can withstand the loads needed for the exterior wall and roof applications.

-

What is EPS?

EPS is expanded polystyrene. One cubic meter of EPS contains about 10 million beads, and makes up approximately 3,000 closed cells, which are filled with air. Since EPS is 2% polystyrene and 98% air, it acts as an excellent thermal insulator.

SIPs vs. Traditional Framing